The Process of Installing Transit Surface Applied Tactile

Surface applied tactile tiles are often used in transit applications such as commuter rail, subways, light rapid transit, monorails, and bus stations. They have emerged as a requirement for public transportation facilities under Title II of the American’s with Disabilities Act (ADA), which forbids public transportation authorities from discriminating against people with disabilities.

Tactile warning surfaces provide feedback for anyone using a cane, walker, wheelchair, or any other assisted device where there’s a transition between a safe path of travel and areas of traffic.

Truncated dome tiles are found along walking paths, in parking lots, on curb cut-outs, wheelchair ramps, and at building entrances. To function as intended, surface applied tiles must be installed properly. They are not set in concrete. This allows for more flexibility, and it allows existing surfaces to be retrofit without being repaved.

ADA Solutions makes the installation process easy, but here is a look at the installation process, with tips on ensuring a safe and secure fit.

Select a Product

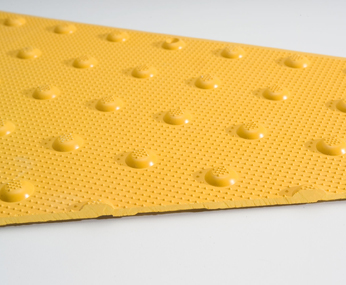

Tactile tiles must meet specific requirements, including a material composition of exterior-grade glass and carbon-reinforced polyester material, and being uniform in color, as is the yellow tactile tile we offer for transit applications. A square grid of raised truncated domes must meet the Federal Code of Regulations requirements. All domes must be 0.2 inches high with a center-to-center spacing of 2.35 inches. At ADA Solutions, all our products meet the latest requirements and the highest quality standards.

Consider the Weather Conditions

Tactile tiles should not be installed where there is standing water or other extremely wet conditions. The ideal installation environment is one that’s clean and dry, but tiles can be installed where it is slightly damp. Installation should not be performed if rain is imminent. The colder the temperature, the longer it will take for the adhesive to cure. Ideally, air/surface temperatures should be above 40°F, but temperature conditions are less restrictive in terms of going ahead with the installation.

Make Sure Concrete Has Cured

Allow the concrete surface to cure for at least seven days before preparing it for installation of transit tile. The substrate must be clean and any damage must be fixed before commencing installation. It must also be level to within a fraction of an inch, and platform edges need to be completely or nearly straight. Tolerances must be within 1/8 to 1/4 inches over a 12-foot length of the platform.

Prepare the Surface Accordingly

The flanges of the tile will need to fit properly. To prepare the surface accordingly, parallel to the edges of the platform make saw cuts that measure 3/8 inches wide by 3/4 inches deep. An overall recess of 1/4 inch deep must be created. This ensures the tile sits flush with the platform surface.

Placement

Tactile warning tiles should be placed within the dimensions of a platform and exceed its edge as little as possible. Successive tiles can be installed, but each must have a uniform joint of at least 1/8 inches in between. These separating joints allow for expansion and contraction of the surface tile.

In general, only uncut tiles should be used, and a tile should never measure less than 12 inches long. Truncated domes should align between successive tiles whenever possible. When cutting, if this is necessary, grind off the dome if there’s less than half of it left. If there’s more than half a dome left, it should be beveled.

Apply the Adhesive

Applied on the backside of the tile, the adhesive should be spread across this surface in 12 to 15 spots, including where the fasteners will be secured, to create an effective seal. Use a square notch trowel to apply the adhesive. Curing takes about 24 to 48 hours once the tile has been positioned onto the platform.

ADA Solutions recommends Chem Link M-1® Adhesive/Sealant. This high-strength, one-part adhesive is polyether-based and low odor. It is also VOC-compliant and solvent-free. Providing a strong bond to properly prepared concrete substrates, it is also suited as a perimeter sealant and provides an adequate finish for tactile warning surface panels.

Before applying the adhesive, the surface must be clean and free of loose materials and projections. All voids must be filled. The surface must be clean, damp, or dry and completely smooth. If any contaminants, such as oil, grease, wax, or other sealers and curing compounds, are present, then the adhesive may not properly bond to the surface.

M-1® Adhesive/Sealant cures within 24 hours and can be cleaned from tools, equipment, and panels with isopropyl alcohol. Coverage depends on the type of product used. For five-gallon containers, apply a gallon per every 45 to 60 square feet of substrate; with the 10.1-ounce Adhesive Cartridges, use one cartridge per every 10 square feet of panel.

Use of Fasteners

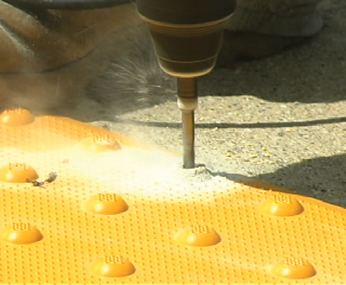

Our tactile tiles contain 15 countersunk holes, but fastener holes can be drilled up to 1/4 x 2½ inches, being as straight as possible, to improve installation results and compensate for any irregularities with the surface substrate. To set the fastener, a hammer and punch pin can be used if necessary. When new holes are needed, drill them straight through the center of truncated domes. Any additional fastener used must be flush with the dome.

Drilling fastener holes generates dust, which can be dispersed with a leaf blower. Fasteners must also be placed, both across the width of the tile and on either side of expansion joints, within four hours of placement. Once properly fastened, the tile is then sawcut near the centerline of the expansion joint. Next, apply sealant in each sawcut, making sure it is flush with each tile’s bevel. Any excess sealant can be cleaned with a damp cloth and acetone.

If there is frequent activity during an ongoing project, protect the tiles during curing or while the site remains under construction by placing hardwood or plywood over them. Also, follow any other manufacturer specifications provided.

Order Transit Tactile Tiles from ADA Solutions

We are the leading manufacturer of detectable ADA warning surfaces in North America. Our products are engineered to improve public access and mobility for the visually impaired and other persons with disabilities. With over 1,500 distribution centers, we serve distributors, their customers, and communities across North, Central, and South America.

In addition to surface-applied, we offer cast-in-place tile, composite pavers, and monolithic pre-cast blocks, as well as wayfinding, graphic tiles, and tactile wall tiles for a wide range of applications with the highest commitment to quality and innovation.

Call us at 800-372-0519 to learn more or receive a free quote.