Americans with Disabilities Act (ADA) requirements continue to be updated more than three decades after the law was passed, with mandates still in place to make public areas accessible to wheelchairs, walkers, and motorized scooters through the use of ramps.1

This means your facility needs to have an ADA-compliant ramp for 2021 if it serves the public, and adhere to the type of ramp required. Location, size, and slope are just some factors to consider. The same requirements are in place, with just some proposed changes to language thus far; these include parallel execution of constructs such as loops, blocks, and container iteration as well as parallel reduction.2

Importance of an ADA Curb Ramp

For people with disabilities, curb edges and other hazards can be quite dangerous. ADA curb ramp requirements are in place to help prevent situations such as people falling out of wheelchairs or scooters, or tripping while using a cane or walker. Accessibility is an factor too, as federal laws consider restricting access in public areas to be a form of discrimination.3

To help you better understand the latest ADA ramp specifications and requirements, we will answer some questions we often get from business owners, building managers, and construction companies.

Where are curb ramps and ramps required by the ADA?

The ADA requires curb ramps and ramps to be installed along any accessible route in a public area, along a path where there’s a change in height greater than ½ inch. As an alternative, a facility may use elevators or platform/chair lifts to provide accessibility.1 In addition, accessibility routes with a 5% or greater slope must be fit with ADA-compliant ramps.

Section §405 of the ADA curb ramp requirements for 2021 covers the following ADA curb ramp design standards:

- Clear Width: A ramp run must be at least 36 inches wide between the ramp’s handrails.

- Rise: A maximum of 30 inches per run, with no limit on the number of runs.

- Running Slope: 1:12 maximum slope, or one foot in elevation change for every 12 feet.

- Cross Slope: The ADA permits a maximum ratio of 1:48.

- Alterations: Are permitted on running slopes with limited space, such as:

- 1:10 maximum with 6 inches maximum rise

- 1:8 maximum with 3 inches maximum rise

- A slope of no greater than 1:12

What are some additional requirements for curb ramp dimensions?

A curb ramp must occupy a space 36 inches wide, not including handrails. Railings are required if the ramp rises more than 6 inches. Its width must not be reduced by indentations, flared sides, or other design features. The only exception is when equipment essential to any work being performed is used.1

An excessively long ramp run can be difficult to navigate with a wheelchair or walker. However, the ADA doesn’t restrict length so long as a curb ramp or ramp doesn’t exceed 30 inches in height. Larger ramps can be configured as a series of smaller rises, or a chair or platform lift may be used instead.

What do the slope requirements for curb ramps and ramps mean?

Slope is the ratio of the height of a ramp to its length. An ADA curb ramp must have no more than a 1:12 ratio, or no greater than a 8.33% slope. The ADA also requires slopes to be consistent from end to end; a ramp must have a uniform slope. There are only a few exceptions to this rule, which are dependent on building materials.

Cross-sloped ramps are the only other exception. The maximum ratio for cross slope here is 1:48. Side flares used with certain curb ramp designs are limited to only a 1:10 ratio.1

What Are the Latest ADA Requirements for Landings?

A landing, which must be installed at the top and bottom of a ramp (in between separate sections), must be at least 60 inches long and 36 inches wide.1 Its level must not exceed a 1:48 ratio.1 For intermediate landings between runs, there must be at least 60 inches of clear width and a 60-inch minimum length. Handrails, vertical posts, edge protectors, or other elements cannot obstruct the path.

Handrail extensions are also required at the top and bottom of a run. They must be at least 12 inches long. Although the extension must travel in the same direction as the ramp, it can turn or wrap with a handrail so long as it is continuous, or follows the inside turn of a dogleg or switchback type ramp. The design of curb ramps and ramps, landings, and the bottom of curb transitions must also prevent water from pooling.

Doorways can be installed at ramp landings. In such cases, ramps can overlap with door openings but the door cannot open into the landing area. Sometimes it’s hard to avoid an overlap. If this can’t be avoided, the ADA recommends the door be configured to swing open in the direction opposite the landing.

Are side flares required?

Side flares reduce the risk of tripping. They are not required on curb ramps but are essential when there’s not enough space for a top landing. A wheelchair user might need a side flare for maneuvering if landing space is restricted. Parallel-type curb ramps can be installed to ease maneuvering in such an instance.

However, side flares generally don’t provide the space to accommodate wheelchairs. This can be addressed by altering the curb ramp accordingly. The landing must be at least 36 inches long and have room for a person using a wheelchair to approach, exit, or turn on the ramp without contacting the compound slope’s flared side.

Where can built-up curb ramps be used?

The ADA permits built-up curb ramps. These are added off a curb to provide access, and can either be built up to the curb in the street or cut through it. They can also be used in parking lots. However, built-up ramps cannot project into parking spaces, traffic lanes, or access aisles.

Built-up curb ramps can feature side flares with a 1:10 maximum slope on either side. Alternative designs can be used when a built-up curb ramp is not feasible. An alternative ramp must run parallel to the sidewalk with landings at least 48 inches or wider at its base.1

Can a curb ramp or ramp be curved or circular?

A curved or circular ramp does not meet ADA standards as it’s not safe or practical for a wheelchair user. Its radius must be large enough to provide a compliant cross slope. Compounding slopes violate ADA curb ramp requirements unless the cross slope is compliant. The ramp must have a level landing wherever there are changes in direction, or else there will be an uneven surface.

Can a ramp be portable or added later?

Only if it serves a temporary structure. Otherwise, all curb ramps and ramps must be installed during initial construction or when alterations are performed. The only exception is when access to a raised workstation or courtroom is required.

Can raised crossings be used instead of curb ramps?

This is permitted if the entire crossing is at the same elevation as the curb. By installing a raised crossing, a curb cut is eliminated, and the installation can help reduce the speed of traffic. However, requirements for height, width, and markings may vary with local regulations.

What are the requirements for curb ramps at islands?

ADA compliant sidewalk ramps at either side of the island must be separated by at least 48 inches. Individuals using wheelchairs therefore have room to pass one ramp before reaching the second one. A level cut-through can be used if the island isn’t wide enough.

What are the requirements for curb ramps used at intersections?

According to ADA curb ramp design standards, ramps used at a marked crosswalk must be fully contained within that crosswalk. While crossings are not required to be marked, ramps must be placed perpendicular to corners within the allotted space. Flared sides are excluded from these requirements. The ramp opening can align with the curb line or be oriented towards the crosswalk.1

Are diagonal curb ramps allowed?

A diagonal curb ramp can be used at a crosswalk. It eliminates the need for two separate ramps. There must be 48 inches of clearance at the bottom and segments on either side, beyond the flares, that are 24 inches long. The transition of the ramp to the street must be contained within the marked crossings of both crosswalks.

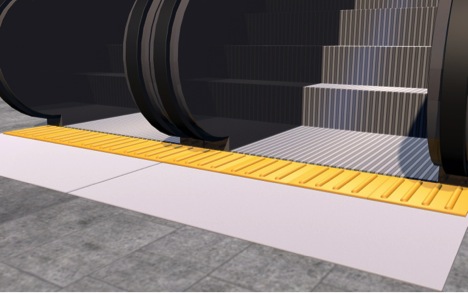

Detectable Warning Systems and Ramps and Curb Ramps

Aside from specific requirements for ramps and curb ramps, the ADA also includes a section regarding the use of detectable warning systems on accessible routes. The use of tactile raised domes, also called truncated domes, at the top and bottom of ramps is not always required. However, they are mandatory in subways, train stations, and bus stations, and other public transportation areas.

Where are detectable warnings required on curb ramps?

ADA-compliant curb ramps with tactile warnings are required at bus, rail, and other facilities operated by federal agencies, as well as intercity and commuter rail stations. Detectable warnings must be provided on boarding platforms with an open drop-off (private sector facilities included). The Department of Justice (DOJ) and Department of Transportation (DOT) also require the use of detectable tactile warning systems. Their requirements can be added on top of those of the ADA.

The DOJ and DOT require raised domes for curb ramps to be used in areas that receive funding from the Federal Highway Administration, as well as in federal, state, and local government facilities.

The ADA also recommends other facilities install panels with truncated domes to warn visually impaired individuals of changes in surfaces. This includes the top and bottom of ramps. That’s because people use ramps and curb ramps even in areas where federal, state, or local requirements don’t mandate them.

Why are tactile warnings not required for all curb ramps?

The Access Board has specific criteria for public rights-of-ways, specifically public streets and sidewalks used by people with vision impairments. Tactile warning surfaces are also not required in all hazardous vehicle areas, especially where reducing vehicle speeds, installing speed bumps, and using marked crossings are viable options.

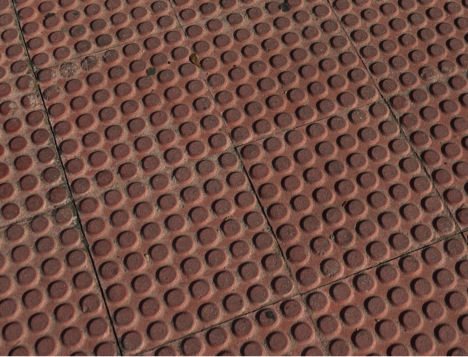

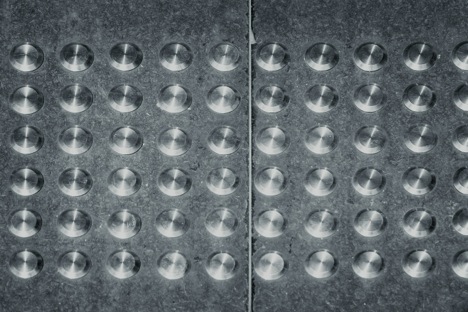

However, when tactile warning curb ramps are required by federal, state, or local laws, they must comply with specific guidelines for spacing, size, and contrast with the regular pavement surface. For instance, California laws have adopted the use of yellow as the only allowed color, with a few exceptions. Overall, the ADA requires that a truncated dome has specific dimensions:

- Height: 0.2 inches

- Base diameter: 0.9 to 1.4 inches

- Size: 50% to 65% of the base diameter

- Dome spacing: At least 0.65 inches from edge to edge, and distance of 1.6 to 2.4 inches from the middle of one dome to the middle of another.1

Depending on the location of warning surfaces, placement can vary. While in some areas tactile surfaces are only needed in transition zones, they must run the entire length of a subway and rail station platform.

At ADA Solutions, we offer cast-in-place replaceable, surface applied, and radius systems in a variety of colors. Cast iron and photoluminescent systems are available as well. For more information about ADA curb ramp requirements for 2021 and assistance in selecting the appropriate tactile warning systems for your facility, please feel free to contact ADA Solutions at (888) 927-2043 today!

Sources:

- https://www.access-board.gov/ada/guides/chapter-4-ramps-and-curb-ramps/

- www.ada-auth.org/standards/2xrm/html/RM-0-2.html

- https://www.ada.gov/pcatoolkit/chap6toolkit.htm

- https://www.ada.gov/regs2010/titleII_2010/titleII_2010_regulations.htm#subpartd