RADIUS TACTILE SYSTEMS

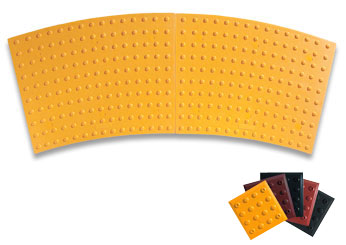

Our innovative curved tactile system is designed to help installers successfully accommodate radius conditions with ease, accuracy, and code compliance. Constructed with the same industry-leading workmanship as our rectangular panels, the Radius Tactile System developed by ADA Solutions is a popular innovation among our quality-conscious contractors, engineers, architects, project managers, and government representatives who need curved detectable warning surfaces for their sites. Use this system with our ADA Radius Calculator to determine accurate panel quantity and cut dimensions for each installation with radius conditions.

What Are Radius Tactile Systems?

Each tactile panel is a detectable warning tile that meets the detectable warning surface requirements of the latest Americans with Disabilities Act (ADA) standards. Each is of a uniform color and made of a glass and carbon-reinforced polyester composite material. Per current standards, domes are arranged in a square grid pattern. These raised truncated domes are 0.2” in height, with a base diameter of 0.9”, and spaced at 1.6” to 2.4” apart per the Federal Code of Regulations.

The pattern provides a wheelchair or walker user with tactile feedback. For optimal results, a 2.35” horizontal and vertical center-to-center dome spacing is preferred. Radius SA tile in the standard dome spacing range is required to have dimensions of 24” x 33.25”.

The difference between our standard panels and radius (curved) solutions is the ability to follow the contour of sidewalk curbs, curb ramps, and other surfaces. Individuals using a wheelchair, walker, or shopping cart, or anyone who is visually impaired will feel the curved truncated domes. The tangible feedback from these tactile warning surfaces notifies them they’re close to the edge of a roadway, for example, where traffic or other dangers may be.

Features and Advantages:

- Ideally engineered for applications where radius conditions are 6’ to 22’

- No cutting required where radius = 11’ to 13’

- Pre-scored for 10’, 15’, and 20’ radius

- Cut to fit within minutes

- High degree of slip resistance and UV stability

3–Part Cast-In-Place Replaceable Radius Product Specification: ![]()

3–Part Cast-In-Place Replaceable Radius Product Specification: ![]()

3–Part Surface Applied Radius Product Specification: ![]()

3–Part Surface Applied Radius Product Specification: ![]()

Radius Calculator (Imperial Units): ![]()

Radius Calculator (Metric Units): ![]()

RADIUS TACTILE DRAWINGS

Product Applications

Our detectable warning panels are available in numerous formats to accommodate individual applications. As for the radius solutions, the following types are offered:

· Cast-in-Place Replaceable (Wet-Set)

Each panel is placed onto concrete that has been poured and finished level and to its required dimensions. The ADA Replaceable Tactile Unit is then fixed into the wet concrete using a rubber mallet. A piece of wood may be used as well. Once in place, the unit must be left undisturbed until the concrete cures; in about two to four hours, the surface can tolerate pedestrian traffic.

Panels can be removed and replaced as well. Each one is anchored with composite bolt caps and heavy-duty steel bolts and washers. These are removed, and a rubber mallet is tapped along the sides in a grid pattern; then the unit is pried (at its edges) from the concrete ramp with a prybar. A new unit can then be installed in the concrete ramp impression.

· Radius Tactile – Surface Mount

A surface mount tactile panel is placed on a clean, moisture-free surface. Instead of placement in a depression or pre-cured concrete, it is laid on top of the substrate. It can be cut to fit, as needed, and then an adhesive is placed along the bottom edges. The panel is placed on the ground with the tactile surface facing up, holes are drilled, and fasteners are used to secure the panel to the pavement. A caulking compound is then applied around the perimeter of the panel.

Our Curved Detectable Warning Surfaces Meet ADA Accessibility Guidelines

ADA Solutions’ Radius, Cast-in-Place Replaceable (pre-assembled, anchored panels), Surface Applied, and Cast-in-Place composite panels provide tactile feedback for those on foot and using any type of rolling device (wheelchair, walker, stroller, etc.). Contact is also detected by those operating street cleaning equipment and other vehicles.

Why Choose ADA Solutions?

For more than twenty years ADA Solutions has been a respected manufacturer of detectable warning surfaces that have been successfully installed at many publicly accessible sites across the country. Our ISO 9002-certified facility in Ohio provides us with the tools, equipment, and on-site expertise we need to create reliable, long-lasting products that comply fully with the guidelines of the Americans with Disabilities Act. All of our ADA-compliant solutions come with a seven-year warranty.

Whether you need a curved ADA ramp for your location or another one of our curved detectable warning surfaces, you can trust our products to get the job done. To learn more about our curved tactile walking surfaces, feel free to contact us at your earliest convenience.