For those who are not disabled, the relative ease of daily tasks is often taken for granted. The non-disabled have few problems getting to work, running errands, or crossing a busy street; the world has largely been designed for this majority. For a disabled person, however, the experience is very different. A visually impaired person, for example, may be unable to drive to work, have trouble using crosswalks, or be injured by a hazard he or she cannot see.

According to the World Health Organization, more than one billion individuals in the world are disabled in some way. Of those, approximately 285 million are visually impaired (having significantly low vision that cannot be helped with corrective lenses alone).¹ In the United States, the National Federation of the blind reports that more than seven million people have some form of visual impairment.²

Unfortunately, even with millions of disabled individuals worldwide, there are still many spaces that aren’t as accessible or safe for the disabled as they are for others. Because of this, the disabled tend to be at greater risk of an accident.

Common Accidents and Their Causes

The following are a few common types of accidents involving disabled persons, as well as their typical causes:

- Falling

- Common causes: Slippery surfaces that could not be avoided or foreseen due to their disability; tripping over hazards (e.g., uneven sidewalks); attempting to go upstairs when a ramp is unavailable.

- Getting Hit by a Motor Vehicle

- Common causes: Failure by drivers to acknowledge pedestrians in wheelchairs; inability to distinguish between the sidewalk and the road (if visually impaired).

- Injury from Objects or Other People

- Common causes: ADA non-compliance and unrecognized hazards (e.g., narrow store aisles), disregard for disabled individuals in a crowded space; lack of appropriate safety measures.

Using ADA Tiles to Prevent Accidents and Support Accessibility

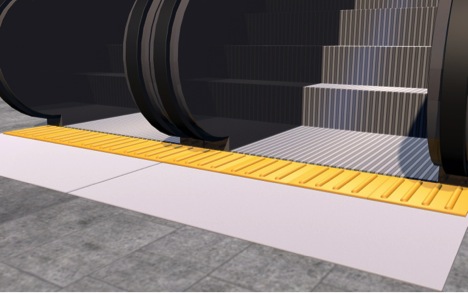

One way to create safe, accessible spaces is to use ADA tiles to alert the visually impaired to areas bordering roadways, parking lots, and other areas of potential danger. ADA-detectable warning tiles feature a unique textured surface that can be felt through most types of footwear, providing a tactile alert to the person that he or she is approaching a curb or crosswalk. This type of warning is especially important now that curb design has become more sloped, making it more difficult to feel for the edges.

The use of ADA warning tiles for accident prevention and accessibility has numerous benefits for those installing them, as well. Using modular tiles to create tactile warning surfaces makes the application simple, flexible, and easy to replace. Focusing on accessibility and safety for the visually impaired also ensures that businesses aren’t alienating an entire group of potential customers.

The Unique Design of Detectable Warning Surface Tiles

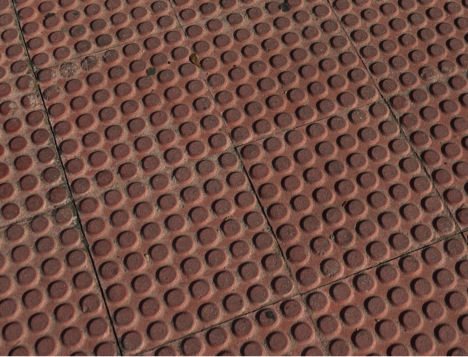

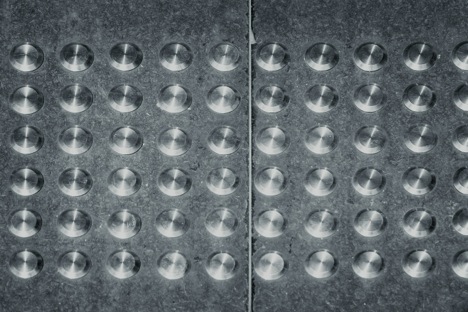

Perhaps the most important aspect of tactile surface tiles is their carefully planned texture. While the bumps on the surface of the tiles may seem arbitrary, they’re manufactured to specifications provided in the Americans with Disabilities Act Accessibility Guidelines (ADAAG). The shape, known as the “truncated dome,” has been determined to be ideal for detectability and overall surface safety. To be compliant with the ADAAG, each dome must be within the defined height, diameter, and spacing ranges.

It’s not just about the truncated dome, however; every aspect of an ADA-detectable warning tile’s design is intended to support safety for everyone who might come in contact with it. The texture, for example, is important not just for being easily detected by visually impaired persons; it’s also perfect for providing grip in otherwise slippery conditions.

ADA tiles can also be manufactured in a variety of colors, the most popular being a bright, easily visible shade of yellow. These different color options make it possible for development planners to create high contrast between the tiles and their surrounding surfaces, making the tiles ideal as visual cues for the sighted.

Your Obligations as a Business Owner or Public Servant

If you own a business or are responsible for planning a public space, you’ll need to make sure that your plans meet certain safety and accessibility standards. In addition to obeying all relevant building codes in your area, you have an obligation to meet ADA accessibility guidelines so that disabled individuals can easily access the space and be protected from accidents.

The ADAAG cover a variety of topics, including (but not limited to) the following:

- Minimum accessibility requirements

- Accessible room design

- Bathroom stalls

- Object heights (sinks, mirrors, hand dryers, soap dispensers, light switches, etc.)

- Building entrance ramps

- Detectable warnings (ADA flooring, ADA walkway requirements)

- Detectable through footwear by the visually impaired

- Sizing (minimum 6-8 inches from back of curb)

- Truncated dome texture design

- Signage

- Curb Ramps

- Usable by those with walkers, wheelchairs, scooters, etc.

- Sloped transition from the street up to the walkway

- Design of accessible routes

- Doorways, elevators, hallways, etc.

- Appropriate slope and width measurements

- Alternatives to stairs

- Sufficient turning space (for wheelchairs, scooters, etc.)

While following all of these different regulations might seem like unnecessary red tape, remember that they exist to protect and support the needs and safety of everyone, regardless of their abilities. It’s also not as difficult or time-consuming as you might think; ADA Solutions’ detectable warning surfaces, for example, are easy to order, install, and replace as needed.

Before you solidify your plans or do any installations, make sure that you look into all of the relevant construction, safety, and accessibility laws in your state and community. Depending on where you live, you may have other legal requirements in addition to the federal ADA guidelines.

ADA Solutions Is an Industry Leader in Detectable Warnings

Whether you need ADA tiles for new construction, to correct compliance issues, or to replace old worn-out surfaces, you can trust the superior warning tile products at ADA Solutions. Our fully ADA-compliant tiles are made from heavy-duty materials like cast iron and fiberglass polymer composites, giving you years of reliable function without wear. Our tiles are also UV stable, which means that even years in direct sunlight won’t change their color or contrast.

ADA Solutions offers a range of detectable warning surface products for various applications:

-

- Cast-in-place tiles (standard or replaceable)

- Delivered ready for installation in freshly poured concrete.

- Made from durable composite materials, ideal for long-term use.

- Replaceable version has a surface piece that is anchored into panel body for easy replacement after years of wear.

- Surface applied tiles

- Ideal for retrofitting and quick installation (5-10 minutes, in some cases).

- Thin, bevel-edged tiles provide a safe transition when installed on the surface of existing concrete.

- Radius systems

- Designed to support accessibility and ADAAG compliance along curved areas (radius conditions).

- Easy, fast cutting with pre-scored radius measurements at 10, 15 and 20 feet.

- No cutting needed for radiuses of 11-13 feet.

- Cast iron “Irondome” tactile systems

- Exterior grade tactile warning surface tiles cast from solid, extremely durable iron.

- Natural finish of cast iron meets ADA color requirements.

- Eligible for LEED® points (ideal for businesses seeking LEED® certification).

- Replaceable graphic tile systems

- Custom-designed tiles featuring full four-color graphics, messaging, and/or advertisements.

- Artwork can be displayed across one or more tiles.

- Replaceable for easy updating of graphics and messaging.

- Other products

- Photoluminescent “Glow-Dome” systems.

- Wayfinding surfaces.

All of our tactile warning surface products are designed to meet ADAAG standards. With appropriate installation, our tiles provide full compliance and maximum accessibility.

To learn more about how you can prevent accidents involving the disabled and meet your obligations to safety and accessibility, explore our products online or call ADA Solutions at (800) 372-0519.

Sources

1. http://www.who.int/blindness/GLOBALDATAFINALforweb.pdf